CAD CAM CNC

We use LibreCAD, FreeCAD, and Fusion360 as our primary CAD programs. For simple 2.5D machining, we sometimes manually write the G-Codes, especially for production machining when we want greater control over tool paths. We also use VisualMill and Fusion CAM packages to generate tool path directly from CAD files, especially for pocketing and 3D tool paths.

For general machining, we use a Haas VF-2SS VMC, vertical machining center, a Haas ST-20SS CNC lathe for production turning, a Haas TL-2 CNC lathe for prototyping and short runs, and a Haas SR-100 CNC router for machining metal, wood, and plastic sheets.

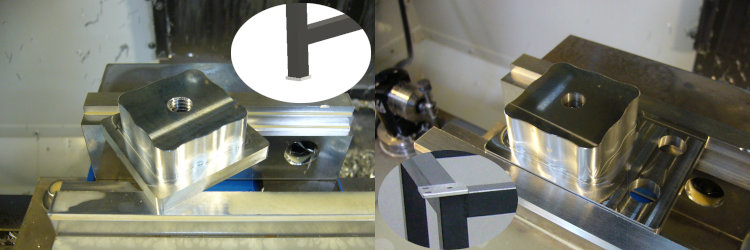

Work Table No4 - Endcap Fastener Machining

The aluminum leg levelers and table top fasteners were CNC machined. These two parts server as the bottom and top encaps to the 2inch square tubing.

The aluminum leg levelers and table top fasteners were CNC machined. These two parts server as the bottom and top encaps to the 2inch square tubing.

06-20

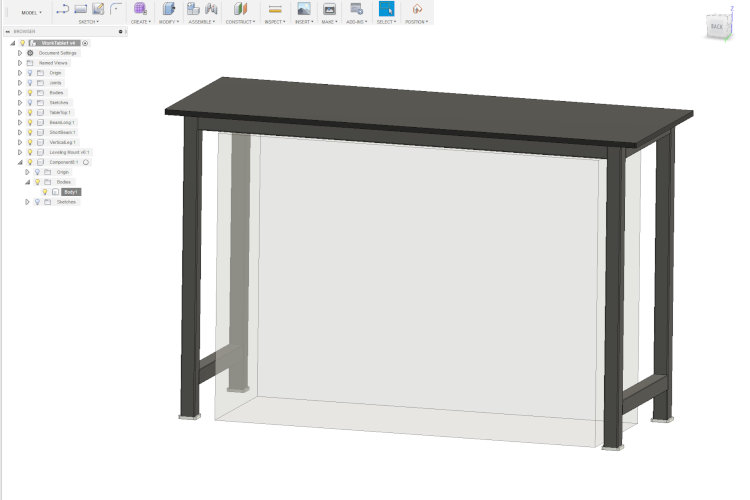

Work Table No4 - Design

Fusion 360 was used to create the Work Tabel design to check the dimensions. A 52" 10 Drawer Craftman rolling tool cabinet will be nested underneath the table. Based on previous experience TIG welding the table frame, the challenge will be meeting the +/- 0.125" concentric table post dimension to fasten the frame to the tabletop via the CNC machined aluminum fastener blocks.

06-01