Rethink Robotics Sawyer - Initial Test

Initial programming and functional testing of Rethink Robotics Sawyer robot.

07-17

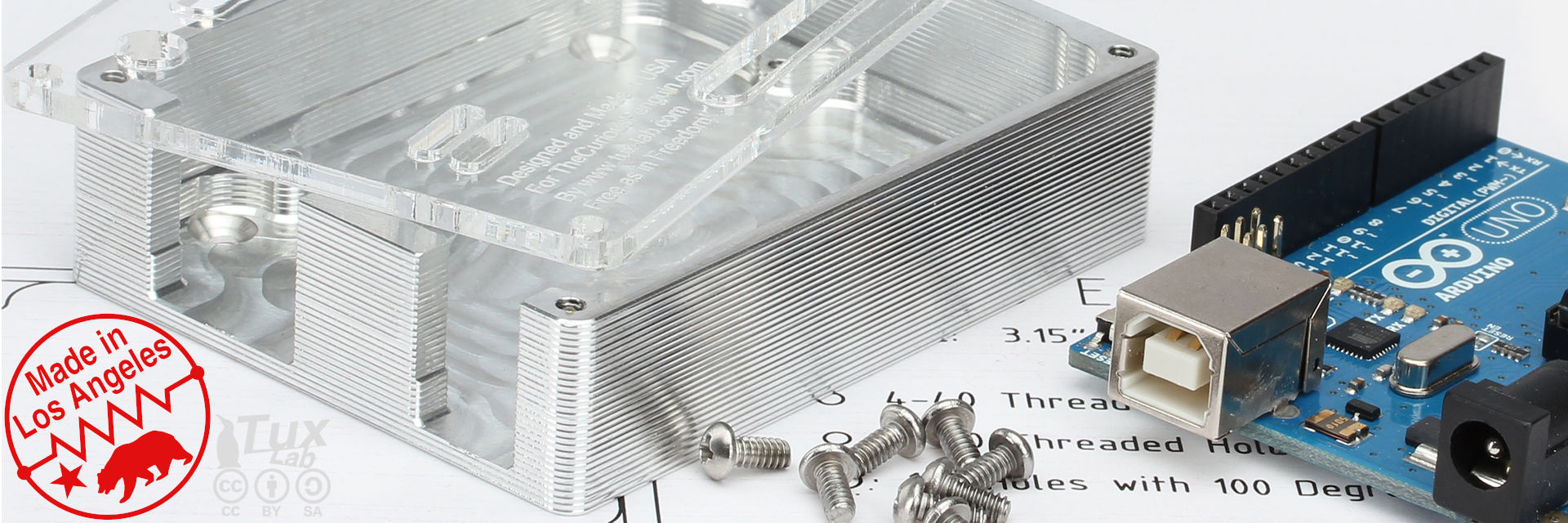

Work Table No4 - Assembly & Use

The tabletop edges were masked, then coated with contact cement, before attaching the Formica laminate, followed up with trimming with a handhelp router. Work Table #4 is placed into service as the primary mechanical assembly table. A Craftsman 52" 10 Drawer tool chest (US Made) was rolled underneath the table for parts storage.

07-02

Work Table No4 - Endcap Fastener Machining

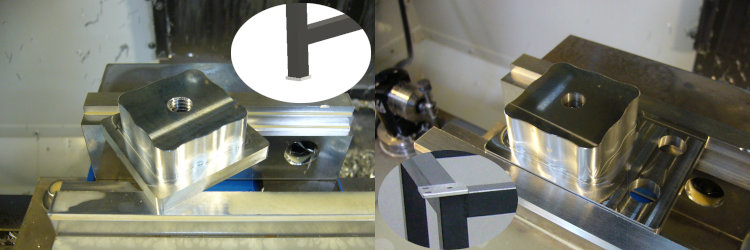

The aluminum leg levelers and table top fasteners were CNC machined. These two parts server as the bottom and top encaps to the 2inch square tubing.

The aluminum leg levelers and table top fasteners were CNC machined. These two parts server as the bottom and top encaps to the 2inch square tubing.

06-20

Work Table No4 - Steel Frame Fabrication

The steel table frame was clamped and TIG welded. Previous attempts, Work Table #1 ~ #3, were tack welded before welding of opposite corners and seams. Yet, warping was still very noticiable and resulted in frame to tabletop misalignment. For iteration, the welding clamps were kept on through out the welding process and that seemed to have greatly reduced the frame warpage issue.

06-10

Rethink Robotics Sawyer

Rethink Robotics's Sawyer Collaborative Robots are designed and manufactured in the United States of America. The robotic arm has 7 degrees of freedom with a reach of 1026mm (~40 inches) with a camera built into the wrist. The operating system is ROS based.

06-04

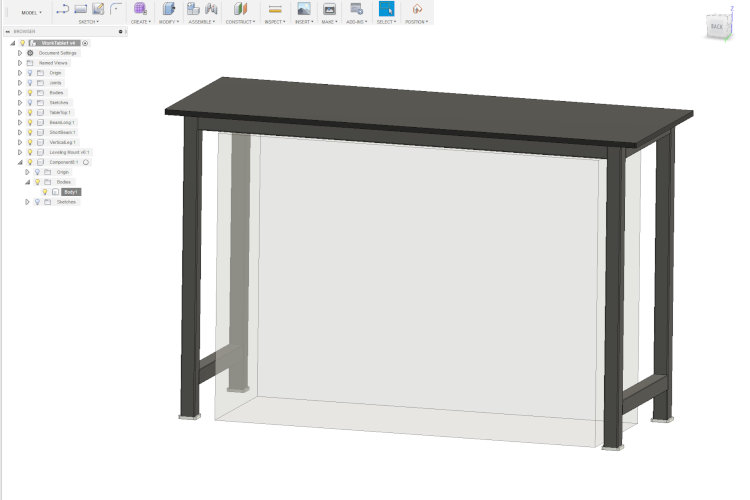

Work Table No4 - Design

Fusion 360 was used to create the Work Tabel design to check the dimensions. A 52" 10 Drawer Craftman rolling tool cabinet will be nested underneath the table. Based on previous experience TIG welding the table frame, the challenge will be meeting the +/- 0.125" concentric table post dimension to fasten the frame to the tabletop via the CNC machined aluminum fastener blocks.

06-01